Here at Hualian Catalyst, we’re dedicated to finding new ways to improve diesel engine efficiency and reduce emissions. We have developed technologies that are able to tackle the difficulties of contemporary exhaust gas treatment since we know how important it is to have efficient filtering systems. We are pleased to present our ceramic wall flow filters, an essential component in reducing diesel engine particle emissions, to you today.

The Importance of Effective Filtration

Ceramic wall flow filters almost completely remove the carbon particulates over a wide range of engine operating conditions. These filters are essential for maintaining compliance with stringent emission regulations and enhancing air quality. Located in the exhaust gas treatment system of diesel engines, the soot particles in the exhaust gas are captured through the inner wall micro-pores. This filtration process not only helps protect the environment but also improves the overall performance of diesel vehicles. However, as soot accumulates, it can eventually block the filter, leading to decreased efficiency. To counter this, it is necessary to ‘regenerate’ the filtration properties of the filter by burning off the collected particulate on a regular basis. This regeneration process often requires increasing the exhaust temperature in diesel passenger car applications until the collected soot is burned off. Our ceramic wall flow filters are designed to facilitate this process while ensuring optimal performance.

Innovative Design for Optimal Performance

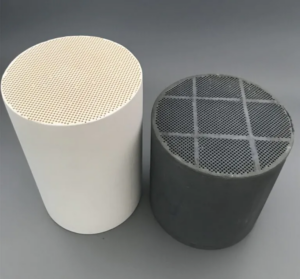

The most effective type of filter we offer is the so-called wall-flow filter. Particulate matter is removed from the exhaust by physical filtration using a honeycomb structure similar to an emissions catalyst substrate but with the channels blocked at alternate ends. The design forces the exhaust gas to flow through the walls between the channels, where the particulate matter is deposited as a soot cake on the walls. Such filters are made of ceramic honeycomb materials, including cordierite, silicon carbide, or aluminium titanate. Our focus on using high-quality cordierite materials in our DPF (Diesel Particulate Filter) ensures durability and efficiency. The unique properties of cordierite DPF allow for effective thermal management, which is essential for maintaining the optimal burn-off temperature during the regeneration process. Additionally, our universal DPF filter can be seamlessly integrated into various diesel engine applications, providing a versatile solution for different vehicles.

Benefits of Hualian Catalyst Filters

Choosing Hualian Catalyst’s ceramic wall flow filters comes with numerous advantages. Firstly, our filters significantly reduce harmful emissions, contributing to cleaner air and compliance with environmental regulations. Secondly, the design minimizes back pressure in the exhaust system, enhancing engine performance and fuel efficiency. Regular maintenance and regeneration of our filters ensure longevity and reliability. Moreover, our universal DPF filter is engineered to cater to a wide range of diesel engines, making it an ideal choice for manufacturers and fleet operators alike. By utilizing our filters, businesses can expect a noticeable reduction in downtime and maintenance costs, as our products are built to last.

Conclusion

In conclusion, Hualian Catalyst is at the forefront of diesel engine filtration technology. Our ceramic wall flow filters are designed to meet the demands of modern diesel engines, ensuring the effective removal of carbon particulates. With features such as the innovative wall-flow design and the use of high-quality cordierite materials, we provide solutions that enhance engine performance while minimizing environmental impact.