- Anyuan Area Industrial Park, Pingxiang, Jiangxi Province, China

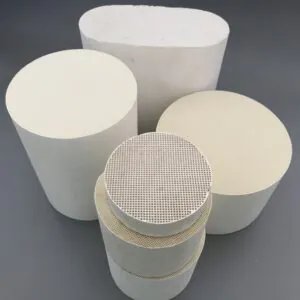

Discover our wide range of ceramic honeycomb catalysts designed for efficient emission control in automotive and industrial applications. The ceramic catalyst boasts a highly porous structure and excellent thermal stability, offering a large surface area for catalytic reactions, low pressure drop, and strong resistance to high temperatures. As an experienced honeycomb catalyst supplier, we offer both standard and custom specifications to meet the unique performance and regulatory needs of global clients.

With a highly porous and structured ceramic substrate, our honeycomb ceramic catalysts are engineered to deliver superior performance in the emission control system.

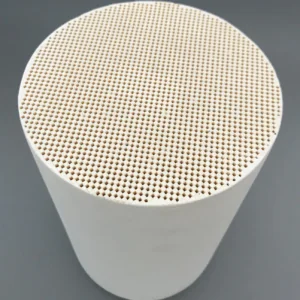

Our automotive exhaust catalyst features a uniform cell design (ranging from 100 to 600 CPSI), ensuring a high geometric surface area. This feature maximizes the contact between exhaust gases and the catalytic coating, greatly enhancing conversion efficiency.

All our ceramic honeycomb catalysts, including VOC oxidation catalyst and auto exhaust catalyst are manufactured from advanced ceramic materials such as cordierite or silicon carbide (SiC). These substrates can withstand extreme temperatures and thermal shocks.

Our ceramic honeycomb catalysts are designed with open-channel honeycomb structures. It allows exhaust gases to pass through with minimal resistance, which not only improves fuel efficiency but also reduces engine workload, helping to extend engine lifespan.

Our ceramic exhaust gas catalyst is formulated with active components such as platinum, palladium, rhodium, or vanadium to effectively support oxidation reactions (DOC), NOx reduction (SCR), and particulate filtration (DPF), making them suitable for a wide range of emission control systems.

All the catalysts meet Euro III, IV, V, and VI regulations, making them a reliable choice for OEMs and markets with regulatory sensitivity.

We offer complete OEM and ODM services, tailoring exhaust gas catalyst solutions to your exact needs—including custom sizes, shapes, cell densities (CPSI), and catalytic coatings. Our custom catalyst is dedicated to making your systems run more efficiently and achieving optimal performance.

A honeycomb ceramic catalyst is designed with a structured honeycomb that maximizes surface area. This design enables better interaction with exhaust gases, making it crucial in reducing harmful emissions in automotive and industrial applications.

Absolutely! The unique honeycomb structure increases contact between the exhaust gas and the catalyst coating. The catalyst promotes chemical reactions that convert pollutants such as CO, hydrocarbons, and NOx into less harmful substances, thereby improving air quality to meet emission regulations.

Our range includes DOC Honeycomb ceramic catalysts for oxidizing harmful gases, Metallic Catalytic Converters that comply with Euro 3/4/5/6 standards, SCR Catalysts for diesel engines to reduce nitrogen oxides, and Sic/Cordierite DPF filters that trap particulate matter.

Yes, many of our honeycomb catalysts are specifically formulated to act as VOC oxidation catalysts, effectively breaking down volatile organic compounds in industrial exhaust streams to reduce pollution.

Absolutely! Hualian is also a leading custom catalyst manufacturer. We provide tailored designs, including various sizes, cell densities (CPSI), shapes, and catalyst coatings, to perfectly fit your needs for engine or industrial system.

Our ceramic honeycomb catalysts utilize high-quality substrates, including cordierite or silicon carbide, coated with precious metals such as platinum, palladium, and rhodium to ensure high catalytic activity and durability.

These catalysts are engineered for excellent thermal stability and mechanical strength, allowing them to withstand high temperatures and thermal shocks commonly found in automotive exhaust systems.

Yes, our products are designed to comply with global regulations, including Euro III, IV, V, and VI standards, making them suitable for a wide range of markets and applications worldwide.

WhatsApp us