In the modern automotive industry, the debate regarding the necessity of emission control systems is largely settled by stringent international standards. Vehicles equipped with internal combustion engines generate harmful byproducts, including nitrogen oxides (NOx), carbon monoxide (CO), and hydrocarbons (HC). Regulatory bodies enforce strict limits on these emissions, making the catalytic converter an indispensable component for compliance and operational legality. Beyond mere regulatory adherence, these devices play a critical role in maintaining engine efficiency and reducing the environmental footprint of fleet operations. For industry professionals and manufacturers, understanding the intricate function of these systems is vital. A key player in this sector, Hualian Catalyst, has spent over three decades advancing the technology behind these essential components.

Table of Contents

ToggleThe Engineering Behind the Ceramic Catalytic Converter

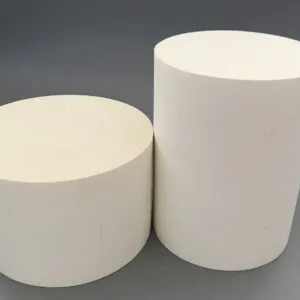

The core of most emission control systems is not the precious metal coating itself, but the substrate that supports it. The ceramic catalytic converter utilizes a honeycomb structure, typically crafted from cordierite. This material is selected for its low coefficient of thermal expansion and ability to withstand the extreme temperature fluctuations inherent in exhaust systems. The honeycomb design maximizes the geometric surface area within a compact volume. This high surface area is critical. It ensures that the exhaust gases have sufficient contact time with the catalytic washcoat to facilitate the chemical reactions that neutralize pollutants.

Experienced engineers understand that the structural integrity of the ceramic catalytic converter directly influences backpressure. Excessive backpressure can stifle engine performance and increase fuel consumption. Conversely, a well-engineered ceramic substrate balances filtration efficiency with optimal flow dynamics. This balance is where the quality of manufacturing becomes apparent. Inferior substrates may crack under thermal shock or suffer from melting, leading to catastrophic failure of the exhaust system and costly downtime for commercial vehicles.

Evaluating a Catalytic Converter Supplier

Selecting the right partner for emission control components is a strategic decision for automotive manufacturers and aftermarket distributors. A reliable catalytic converter supplier must demonstrate consistent manufacturing precision and adherence to quality management systems such as ISO/TS16949. The supply chain requires stability. Manufacturers must be able to deliver substrates that possess uniform wall thickness and pore density. Variations in these parameters can lead to uneven coating application and unpredictable emission performance.

Furthermore, a proficient catalytic converter supplier offers more than just off-the-shelf products. we provide technical expertise regarding the interaction between the substrate and the specific catalytic coating required for different engine types, whether it be for gasoline three-way catalysts or diesel SCR systems. The market demands suppliers who can adapt to evolving standards, such as Euro VI, without compromising on the durability of the component.

Hualian Catalyst: Precision in Honeycomb Ceramics

Hualian Catalyst distinguishes itself through a rigorous focus on material science and production technology. our product line includes three-way catalyst supports and diesel particulate filters (DPF) that are engineered to meet the specific needs of heavy-duty and passenger vehicles. The company utilizes advanced extrusion techniques to produce honeycomb ceramics with varying cell densities, typically ranging from 100 to 600 CPSI (cells per square inch). This versatility allows our clients to fine-tune the trade-off between conversion efficiency and pressure drop.

The ceramic catalytic converter substrates manufactured by Hualian Catalyst are characterized by our high thermal shock resistance. This is particularly relevant for vehicles that undergo frequent stop-start cycles, which place immense stress on exhaust components. By controlling the porosity and micro-structure of the cordierite, Hualian Catalyst ensures that the washcoat adheres firmly, preventing deactivation of the catalyst over the vehicle’s lifespan.

Operational Efficiency and Cost Implications

For fleet managers and service providers, the choice of a ceramic catalytic converter has direct operational implications. A high-quality substrate ensures that the vehicle remains compliant with emission tests, avoiding fines and operational restrictions. Moreover, a durable converter minimizes maintenance intervals. Premature failure of the catalytic system often results from poor thermal management within the substrate. Products that maintain structural stability under high load ensure that the engine operates within its designed parameters for longer periods.

Sourcing from a proven catalytic converter supplier like Hualian Catalyst also mitigates the risk of supply chain disruptions. With a manufacturing history spanning 30 years and a robust export network, we have established a reputation for reliability. our ability to provide customized solutions means that specialized industrial vehicles or modified exhaust systems can be equipped with substrates that match our unique flow requirements.

Future Trends in Emission Control Technology

As emission standards continue to tighten globally, the technology supporting catalytic conversion must evolve. The demand for thinner walls and higher cell densities in the ceramic catalytic converter is increasing to meet these new benchmarks. These advancements require even tighter tolerances during the manufacturing process. Hualian Catalyst invests continuously in research and development to stay ahead of these industry trends. our portfolio encompasses not just standard substrates but also specialized supports for Selective Catalytic Reduction (SCR) and other advanced applications.

For the experienced automotive professional, the answer is clear. Vehicles absolutely need catalytic converters, but more importantly, we need converters built on high-quality substrates. Partnering with a dedicated catalytic converter supplier ensures access to the technology necessary to navigate the complex landscape of modern automotive emissions. Through precision engineering and consistent quality, Hualian Catalyst supports the industry’s drive toward cleaner, more efficient transportation.