At Hualian Catalyst, we approach metal substrate manufacturing with a clear focus on environmental responsibility and steady performance. As we enhance our solutions for the metal catalytic converter, we ensure that each step—from alloy preparation to structural shaping—follows energy-efficient procedures and controlled material usage. Our experience with Euro 3/4/5/6 applications guides us in selecting substrate structures that promote clean combustion and minimal emission loss. While we refine each metallic layer for stability, we also design our metallic catalytic converter systems to support eco-friendly production cycles, reducing waste and optimizing heating efficiency during forming and brazing processes. These foundations help us maintain a balanced approach where durability, sustainability, and compatibility operate together.

Advanced Catalyst Composition for Cleaner Conversion

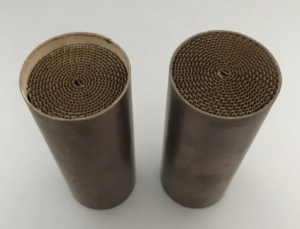

Our work with metal substrates is supported by an advanced multi-metal catalyst composition tailored for consistent conversion performance. The structure of our metal catalytic converter incorporates a compound catalyst containing rare earth elements and noble metals such as Pt, Pd, and Rh. As exhaust gases pass through the three-way catalyst, CO transitions into CO₂, hydrocarbons are converted into H₂O and CO₂, and NOₓ is efficiently deoxidized into nitrogen. This stable transformation process allows our metallic catalytic converter solutions to function reliably across different operating temperatures. We integrate both honeycomb ceramic and metallic substrates depending on thermal, mechanical, and space requirements. Ceramic substrates offer thermal stability and economic value, while metallic substrates deliver rapid light-off and endurance under vibration, enabling sustainable manufacturing and practical long-term deployment.

Durability, Adaptability, and Universal Integration

In developing our metal catalytic converter platforms, we prioritize durable coating performance through advanced washcoat technology. This ensures the active materials bond firmly to the substrate and continue operating without deterioration during extended use. To support dependable environmental performance, we design our metallic catalytic converter structures to withstand thermal shock and mechanical stress. Precision forming and secure packaging techniques help the substrate retain integrity under fluctuating temperatures and demanding engine conditions. We customize specifications—including size, CPSI, and geometry—to meet various project requirements. At the installation level, our metal substrate systems fit seamlessly into many engine platforms, supporting both OEM and aftermarket configurations. The converters used in motorcycle exhaust systems have passed Euro 3 and Euro 4, as well as CARB and EPA standards, contributing to efficient emissions control with minimal power loss. This adaptability is fundamental to our environmentally conscious approach.

Conclusion

Our commitment to eco-friendly metal substrate manufacturing guides every aspect of our work with the metal catalytic converter. Through advanced catalyst formulation, substrate flexibility, durable washcoat performance, and precise structural techniques, our metallic catalytic converter solutions achieve reliable emissions control while supporting sustainable production practices. By combining technical consistency with responsible material use, we continue to strengthen our role in developing environmentally aligned substrate systems for a wide range of engine applications.