Modern diesel engines require reliable solutions to meet strict emission standards, and two critical components in this effort are the aftertreatment diesel particulate filter and the catalyzed diesel particulate filter. We at Hualian Catalyst have invested years in crafting these filters, striving to strike a balance between efficiency, durability, and regulatory compliance. These efforts support clients across a spectrum of industries, from light-duty vehicle operators to heavy machinery users. By continuously refining these technologies, we ensure that each filter bearing the Hualian Catalyst name effectively reduces particulate matter without compromising engine performance.

Table of Contents

ToggleHow Aftertreatment Diesel Particulate Filters Work

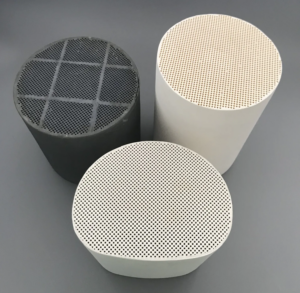

An aftertreatment diesel particulate filter is designed to capture soot and fine particles after they leave the engine, preventing them from entering the atmosphere. Our filters use a wall-flow honeycomb structure that traps over 95% of particulate matter, a design we’ve optimized to keep back pressure low—critical for avoiding engine strain. Whether for urban delivery trucks or construction equipment, this technology ensures vehicles meet Euro IV–VI standards, a requirement we take seriously in every product we manufacture.

The Advantage of a Catalyzed Diesel Particulate Filter

While standard filters capture particles, a catalyzed diesel particulate filter goes a step further by aiding in the oxidation of trapped soot. This catalytic element helps regenerate the filter—burning off accumulated particles at lower temperatures—reducing the need for manual cleaning. We offer this option in both cordierite and silicon carbide (SiC) materials: cordierite for its lightweight and cost-effectiveness in light-duty applications, and SiC for its durability in heavy-duty, high-temperature environments. This versatility allows us to match clients with the right solution for their specific operating conditions.

Custom Solutions and Ongoing Support

At Hualian Catalyst, we understand that no two diesel systems are identical. That’s why we offer customized aftertreatment diesel particulate filters and catalyzed diesel particulate filters, with options for different sizes, cell densities (100–350 CPSI), and shapes. Our team works closely with clients to analyze their needs—whether for a city bus fleet or industrial generators—and recommend the best filter material and design. And with 24/7 technical support, we’re available to assist with everything from installation guidance to troubleshooting, ensuring long-term performance.

Conclusion

The aftertreatment diesel particulate filter and catalyzed diesel particulate filter are essential for modern diesel engines, combining effective particle capture with compliance support. At Hualian Catalyst, we’re proud to deliver these solutions with the quality and customization clients need to keep their operations running smoothly. Whether you’re upgrading a fleet or maintaining industrial equipment, we’re here to provide filters that perform reliably, today and in the future.