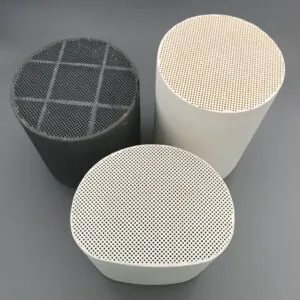

In the competitive landscape of emission control, the performance of a diesel exhaust filter is determined not just by its physical shape, but by the microscopic interaction between the ceramic substrate and the catalytic coating. While the honeycomb ceramic provides the structural backbone, the coating—often referred to as the washcoat—delivers the chemical functionality. For industry professionals, understanding this synergy is key to selecting components that offer long-term reliability. Hualian Catalyst has established itself as a leader in this field by engineering substrates that are specifically optimized to accept advanced coating technologies, thereby enhancing both the mechanical durability and the filtration efficiency of the final product.

Table of Contents

ToggleRefining Filtration Precision Through Washcoat Application

A raw ceramic substrate, typically made of cordierite or silicon carbide, possesses a specific mean pore size, usually ranging from 10 to 20 microns. While effective at trapping larger soot particles, a bare substrate may initially allow finer particulate matter (PM 2.5 and nanoparticles) to pass through until a “soot cake” builds up. Coating technologies solve this initial efficiency gap. When a high-surface-area washcoat (often alumina-based) is applied to the diesel exhaust filter, it effectively narrows the pore channels without blocking them. This process creates a tortuous path for exhaust gases, significantly increasing the probability of interception for even the smallest nanoparticles. The result is a filter that delivers high filtration precision from the very first mile of operation, meeting stringent Euro VI and Tier 4 Final standards.

Catalytic Coatings as a Shield Against Thermal Stress

One of the most counter-intuitive yet vital aspects of modern DPF design is how a chemical coating improves phySICal strength. The primary enemy of a ceramic filter is heat—specifically, the uncontrolled temperature spikes that occur during active regeneration. When soot accumulates, it must be burned off. Without a catalytic coating, this requires temperatures upwards of 600°C. If the soot load is high, the combustion can essentially turn into a kiln fire inside the exhaust, reaching temperatures that can melt or crack the ceramic substrate.

By impregnating the washcoat with precious metals like platinum (Pt) and palladium (Pd), manufacturers create a “catalyzed” filter. This coating lowers the soot oxidation temperature to roughly 300°C–400°C, facilitating continuous “passive regeneration.” By keeping the soot load low and burning it off at cooler temperatures, the coating protects the ceramic structure from thermal shock. Therefore, when sourcing a diesel particulate filter for sale, experienced buyers prioritize coated units because we inherently suffer less thermal fatigue, effectively behaving as “stronger” components over our service life.

Hualian Catalyst: Optimizing the Foundation

A coating is only as good as the surface it adheres to. Hualian Catalyst focuses on the material science of the substrate to ensure optimal coating performance. If a substrate is too smooth, the washcoat may delaminate or flake off under vibration. Hualian Catalyst engineers our honeycomb ceramics with a specialized micro-porosity that acts like a microscopic anchor for the washcoat. This ensures that the catalytic layer remains bonded to the channel walls even under the extreme pulsations of a heavy-duty diesel engine. This strong adhesion is critical for maintaining filtration precision over hundreds of thousands of kilometers.

Chemical Durability and Ash Management

Beyond soot, diesel engines produce ash—a non-combustible residue from lubricating oil additives. Over time, ash can react with the ceramic substrate in a process known as chemical corrosion, potentially weakening the channel walls. Advanced coating technologies act as a sacrificial barrier. High-quality washcoats are chemically stable and can prevent the ash from fusing directly to the ceramic material. This separation makes it easier to clean the diesel exhaust filter during routine maintenance intervals. A filter that can be cleaned without damage is a filter that offers a lower total cost of ownership.

Considerations for the Aftermarket Buyer

For fleet managers and parts distributors looking for a diesel particulate filter for sale, the market offers a wide range of options, from bare substrates to fully catalyzed units. It is essential to verify that the coating technology is matched to the engine’s operating profile. A stop-start delivery truck requires a heavy catalytic loading to maintain passive regeneration in cooler exhaust, whereas a long-haul truck might require less. Hualian Catalyst supports this diversity by offering substrates that are compatible with various coating formulations, allowing for tailored solutions that meet specific operational needs.

Conclusion: The Integrated Solution

The strength of a modern DPF is not defined by the thickness of its walls alone, but by the intelligence of its design. Coating technologies transform a passive ceramic brick into an active chemical reactor that self-regulates its temperature and captures pollutants with microscopic precision. By combining high-grade cordierite substrates with advanced catalytic washcoats, manufacturers like Hualian Catalyst provide the industry with components that survive the harsh reality of diesel operation. For the end-user, this translates to fewer failures, reduced downtime, and a cleaner fleet.