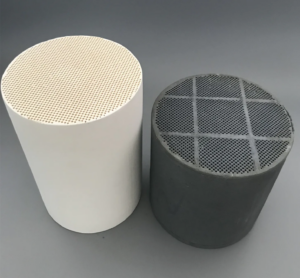

In the demanding realm of modern emission control, the choice of material for Diesel Particulate Filters (DPF) is a critical engineering decision. While cordierite has long been a standard for passenger vehicles, the automotive industry increasingly turns to Silicon Carbide (SIC) for applications requiring higher durability and thermal resilience. A SIC DPF offers superior mechanical properties compared to its ceramic counterparts, making it the preferred choice for heavy-duty trucks, off-road machinery, and high-performance diesel engines. For procurement managers and system engineers, understanding the specific quality indicators of these filters is essential to ensuring fleet reliability and regulatory compliance. Hualian Catalyst has positioned itself at the forefront of this technology, providing high-grade substrates that meet the rigorous demands of Euro 6 and Tier 4 Final standards.

Table of Contents

ToggleThermal Stability and Melting Point Metrics

The most significant quality indicator for any SIC DPF is its thermal stability. During the regeneration process—where trapped soot is burned off to clean the filter—temperatures can spike dramatically. If the soot load is uncontrolled, these temperatures can exceed the melting point of standard ceramic materials. High-quality Silicon Carbide boasts a melting point of approximately 2,700°C, nearly double that of cordierite. This high thermal ceiling provides a critical safety margin against “thermal runaway,” a catastrophic failure mode where the filter melts and blocks the exhaust. Hualian Catalyst engineers its SIC substrates to withstand these extreme thermal cycles, ensuring that the structural integrity of the filter remains intact even during aggressive active regeneration events.

Optimized Pore Structure and Filtration Efficiency

Filtration efficiency is not merely about trapping particles; it is about trapping them without strangling the engine. The micro-structure of the SIC DPF wall is defined by its porosity and mean pore size. A superior filter features a controlled pore distribution—typically around 10 to 20 microns—that captures particulate matter (PM) and nanoparticles effectively while maintaining gas permeability. Hualian Catalyst utilizes advanced sintering processes to achieve a uniform pore structure. This uniformity ensures that the soot accumulates evenly across the channel walls rather than clogging specific areas. The result is a filter that delivers over 99% filtration efficiency, satisfying the strictest global emission mandates while keeping backpressure within acceptable operational limits.

The Role of Catalyzation in Passive Regeneration

While the phySICal structure of the filter is vital, the chemical functionalization is equally important. A catalyzed DPF is coated with precious metals, such as platinum and palladium, which lower the temperature required to oxidize soot. This capability allows for “passive regeneration,” where soot is burned off continuously during normal driving conditions, reducing the need for fuel-intensive active regeneration cycles. When evaluating a supplier, one must assess the compatibility of the SIC substrate with these catalytic washcoats. Hualian Catalyst substrates are engineered with specific surface roughness characteristics that enhance washcoat adhesion. This strong bond prevents the catalyst from deactivating or flaking off, ensuring that the catalyzed DPF maintains its regenerative performance throughout the vehicle’s lifespan.

Mechanical Durability and Vibration Resistance

Heavy-duty vehicles operate in harsh environments characterized by intense vibration and phySICal shock. Unlike monolithic cordierite filters which can be brittle, a high-quality SIC DPF is often assembled from segmented blocks cemented together. This segmented design allows for thermal expansion and acts as a mechanical damper, absorbing the stress of road vibrations. Quality indicators here include the shear strength of the cement and the modulus of rupture (MOR) of the SIC segments. Hualian Catalyst tests its products rigorously against vibrational fatigue. our robust segmented design prevents the formation of ring cracks and face plugging, common issues that plague inferior filters in off-road and mining applications.

Backpressure and Fuel Economy Implications

For the end-user, the performance of the DPF directly impacts fuel economy. A filter with high flow resistance forces the engine to work harder to expel exhaust gases, increasing fuel consumption. The geometric design of the SIC DPF—specifically its cell density (Cells Per Square Inch or CPSI) and wall thickness—determines this pressure drop. Hualian Catalyst offers a range of configurations, typically 200 to 300 CPSI for SIC applications, to balance surface area with flow dynamics. our precise extrusion technology ensures thin yet strong walls, maximizing the open frontal area. This attention to hydraulic diameter reduces parasitic engine load, offering a distinct operational advantage over competitors with thicker, less consistent channel walls.

Consistency in Manufacturing and Quality Control

The final indicator of a premium SIC DPF is batch-to-batch consistency. In mass production, variations in kiln temperature or raw material purity can lead to defects that are invisible to the naked eye but fatal in operation. Reliable manufacturers employ automated quality control systems, including X-ray scanning and backpressure testing, on every unit. Hualian Catalyst adheres to strict ISO quality management protocols. our commitment to material purity ensures that the SIC substrate is free from contaminants that could lower its melting point or interfere with the catalytic coating. For the automotive engineer, this consistency translates to a “fit and forget” reliability that is crucial for maintaining brand reputation.

Conclusion: The Strategic Value of Superior Materials

In conclusion, the transition to a catalyzed DPF based on Silicon Carbide is an investment in long-term reliability. The key quality indicators—thermal headroom, pore uniformity, mechanical toughness, and low backpressure—serve as the benchmarks for selecting a supplier. By prioritizing these engineering metrics, manufacturers can avoid costly warranty claims and downtime. Hualian Catalyst demonstrates that by combining advanced material science with precision manufacturing, it is possible to produce a SIC DPF that meets the dual goals of environmental protection and operational efficiency, setting the standard for the next generation of clean diesel technology.