In the high-stakes realm of automotive emission control, the transition from ceramic to metallic substrates is often driven by the need for superior thermal management and reduced backpressure. For Original Equipment Manufacturers (OEMs) and senior product engineers, selecting the right metallic catalytic converter is not a simple procurement task; it is a rigorous engineering validation process. The component must survive extreme thermal shocks, resist mechanical vibration, and meet stringent regulatory targets such as Euro 6. A failure in the substrate leads not only to non-compliance but to potential engine damage. Hualian Catalyst has spent decades refining the manufacturing processes for these critical components, providing engineers with the technical assurance needed to approve these units for mass production.

Table of Contents

ToggleValidating Foil Alloy Composition and Material Grade

The primary specification that determines the lifespan of a metal substrate is the metallurgy of the foil itself. Unlike the cordierite used in ceramics, a metallic catalytic converter is constructed from high-grade Iron-Chromium-Aluminum (FeCrAl) alloy foils. Engineers must verify that the alloy contains sufficient rare earth elements, such as Yttrium or Hafnium. These elements are critical for forming a stable alumina oxide scale on the foil surface during operation. This scale protects the substrate from high-temperature oxidation. If a supplier utilizes a lower-grade alloy to cut costs, the foil will become brittle and fragment under the exhaust heat. Furthermore, the outer shell housing constitutes a stainless catalytic converter body, typically made from SUS441 or SUS430 stainless steel. This housing material must be verified for corrosion resistance, especially for vehicles operating in saline or humid environments.

Assessing Brazing Integrity and Structural Stability

Mechanical durability is the hallmark of a high-quality metal substrate, but it relies entirely on the brazing technology employed. In the evaluation phase, engineers should inspect the brazing depth and coverage. Top-tier manufacturers like Hualian Catalyst utilize high-temperature vacuum brazing with nickel-based filler metals. This process bonds the foil layers to each other and to the outer mantle. A common failure mode in inferior products is “telescoping,” where the central core is pushed out of the shell by exhaust pressure due to weak or partial brazing. For applications involving high vibration, such as motorcycles or off-road machinery, the structural unity provided by full vacuum brazing is a non-negotiable specification.

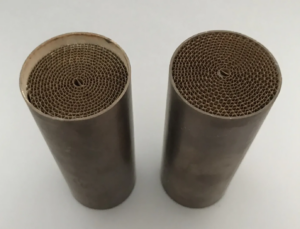

Optimizing Cell Density and Foil Thickness

The geometric advantage of a metallic catalytic converter lies in its wall thickness. While ceramic walls typically range from 0.10mm to 0.15mm, metal foils can be rolled as thin as 0.03mm to 0.05mm. This reduction in wall thickness significantly increases the open frontal area of the substrate. Engineers must calculate the optimal cell density—measured in Cells Per Square Inch (CPSI)—to balance filtration efficiency against engine backpressure. Hualian Catalyst offers a wide range of densities, from 100 CPSI for high-flow performance applications to 600 CPSI for maximum surface area in strict emission zones. The specification sheet must explicitly state the foil thickness, as this directly correlates to the unit’s backpressure coefficient.

Washcoat Adhesion on Metallic Surfaces

Applying a catalytic washcoat to a metal surface presents different challenges than applying it to a porous ceramic. The smooth surface of the metal foil requires a specialized pre-treatment or “washcoat primer” to ensure adhesion. Without this, the precious metal coating will flake off (delaminate) due to thermal expansion mismatches. When evaluating a stainless catalytic converter assembly, engineers should request thermal shock test data specifically regarding washcoat weight loss. Hualian Catalyst employs advanced coating technologies that chemically bond the washcoat to the oxidized surface of the FeCrAl foil, ensuring that the active catalyst remains in place throughout the vehicle’s warranted life cycle.

Thermal Conductivity and Light-Off Performance

One of the distinct performance specifications of metal substrates is our thermal conductivity. Metal heats up faster than ceramic. This property allows the catalyst to reach its “light-off” temperature—the point of 50% conversion efficiency—much more rapidly during a cold start. This is a critical parameter for meeting cold-start emission limits in Euro 5 and Euro 6 standards. Engineers should analyze the thermal mass calculations provided by the supplier. A well-engineered metallic catalytic converter utilizes the low thermal mass of the thin walls to its advantage. Hualian Catalyst provides technical data supporting these thermal characteristics, helping engineers model the expected emission reduction during the initial seconds of engine operation.

Customization of Shape and Dimensions

Unlike ceramics, which require expensive molds for every new shape, metal substrates offer significant design flexibility. The manufacturing process involves winding the foil, allowing for the creation of round, oval, racetrack, or even irregular shapes without prohibitive tooling costs. This is vital for packaging engineers working within tight chassis constraints. When approving a stainless catalytic converter unit, the dimensional tolerances must be strictly reviewed. The gap between the metal core and the canning must be minimal to prevent bypass. Hualian Catalyst leverages this flexibility to provide custom-sized solutions that integrate seamlessly into complex exhaust geometries.

Conclusion: The Necessity of Rigorous Specification

The approval of a metallic catalytic converter is a decision that impacts the fundamental performance of the vehicle. It requires a detailed analysis of metallurgy, mechanical design, and chemical engineering. By strictly defining specifications regarding alloy grade, brazing coverage, and washcoat adhesion, engineers can mitigate the risks of field failures. Suppliers like Hualian Catalyst stand out by meeting these rigorous technical demands, offering products that combine the durability of a stainless catalytic converter housing with the high-performance characteristics of a precision-engineered metal core. For the experienced industry professional, these specifications are the blueprint for reliability.