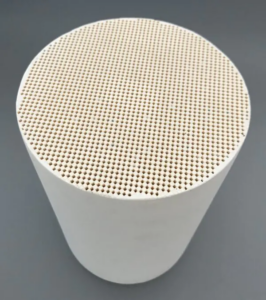

As Hualian Catalyst, we work closely with experienced customers who require dependable diesel emission solutions across diverse machinery categories. At the beginning of every project, we help clients evaluate filtration needs, which often involve a choice between two well-established materials: the silicon carbide option, known as the sic dpf, and the ceramic option known as the cordierite dpf. Our diesel particulate filter system uses a wall-flow honeycomb structure to capture soot and fine particulate matter with stable back-pressure control. By integrating SiC or cordierite structures into the filtration assembly, we support equipment operating under Euro IV–VI requirements while maintaining reliable engine behavior. These material choices allow us to tailor solutions based on thermal stress, duty cycles, and long-term operating patterns.

How the SiC DPF Performs in Heavy-Duty Machinery

In machinery exposed to continuous thermal loads and long operating hours, the sic dpf offers a practical balance between durability and performance. We apply this material in equipment such as heavy-duty trucks, loaders, mining engines, and agricultural power units that routinely face high exhaust temperatures. Silicon carbide’s thermal conductivity helps regulate regeneration cycles and reduces thermal gradients during peak operation. Our company integrates this filter into systems that need predictable soot-loading behavior and consistent regeneration efficiency. While the cordierite dpf remains valuable in moderate-duty engines, SiC becomes more relevant when machinery works under harsh mechanical vibration or rapid temperature swings. At the system level, we focus on predictable filtration, controlled heat release, and long service intervals, which align with the operational demands of heavy machinery users.

Cordierite DPF Uses in Light- and Medium-Duty Equipment

For machinery that operates in varied cycles, including delivery vehicles, compact construction machines, and municipal equipment, the cordierite dpf provides a cost-efficient and thermally stable configuration. Cordierite maintains good thermal shock resistance and manageable weight, making it suitable for systems that encounter frequent stop-and-go operation or moderate exhaust temperatures. We utilize this material when customers need a balanced combination of filtration efficiency, regeneration consistency, and component affordability. When integrated into our system architecture, the sic dpf may still appear in certain auxiliary configurations, but cordierite remains the more practical option for equipment with lighter loads. The filter structure supports the soot-capture process while maintaining stable engine back pressure, helping machinery maintain compliance with established emission standards.

Conclusion and Application Considerations

Across different machinery types, selecting between the sic dpf and the cordierite dpf depends on thermal behavior, duty cycles, and long-term maintenance expectations. Our company evaluates these conditions to provide solutions that support consistent engine performance and effective particulate capture. By applying SiC in high-temperature environments and cordierite in moderate-duty applications, we ensure that each diesel particulate filter contributes to reliable equipment operation and sustained regulatory compliance.