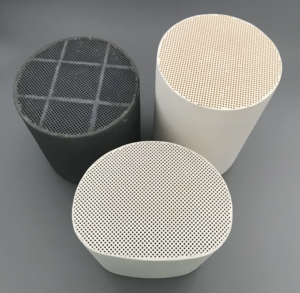

As Hualian Catalyst, we work closely with customers who operate diesel engines under demanding conditions, and we often address concerns about why sic dpf filter systems experience cracking. In our daily technical communication, we observe that operational stress is one of the most common contributors. The SiC/Cordierite DPF (diesel particulate filter) is engineered to trap over 95% of soot and fine particles using a wall-flow honeycomb structure, helping vehicles meet Euro IV–VI emission standards. While both material options perform reliably, the silicon carbide version endures higher thermal loads. When temperature rises rapidly due to aggressive acceleration, heavy towing, or prolonged high-speed operation, the filter may encounter abrupt thermal gradients. These changes cause expansion and contraction across different areas of the substrate, which increases the probability of cracking in a sic dpf filter. We support clients with guidance on appropriate operating ranges to reduce such risks.

Impact of Regeneration Behavior

Cracking often relates to how regeneration cycles occur in real-world applications. Our company has seen engines that trigger regeneration too frequently or too late, which places additional stress on the SiC and Cordierite structures. The SiC/Cordierite DPF relies on controlled regeneration to burn accumulated soot at elevated temperatures. If excessive soot buildup is allowed before regeneration begins, the temperature rise becomes much sharper, raising mechanical stress on the filter walls. On the other hand, overly frequent regeneration increases thermal cycling intensity, shortening substrate life. For heavy-duty engines, the silicon carbide version delivers higher thermal conductivity and offers longer durability, but even SiC can develop cracks when regeneration patterns are irregular. These behaviors explain why users sometimes perceive cracking in a sic dpf filter, especially in conditions where regeneration cannot be carefully managed.

Installation, Back-Pressure, and System Integration

Another reason we observe cracking comes from integration factors rather than material limitations. Proper installation alignment, correct positioning of mounting components, and stable back-pressure are essential for system reliability. Our company has supported many customers in diagnosing vibration-related issues, which can amplify stress on the SiC or Cordierite body. When back-pressure rises due to upstream malfunctions or insufficient exhaust flow, the mechanical load on the filter increases. Even though SiC offers greater mechanical strength for harsh environments, improper installation or excessive vibration can still contribute to structural fatigue. These factors, combined with uneven flow distribution, help explain why cracking appears in a sic dpf filter despite the substrate’s inherent durability.

Conclusion

In summary, cracking in SiC DPF units results from three primary conditions: rapid thermal changes, irregular regeneration patterns, and integration-related stresses. By understanding these factors, we can guide our customers toward improved system stability and longer filter life. Whether selecting Cordierite for light-duty use or SiC for heavy-duty applications, we ensure that each solution aligns with the operating environment and maintenance approach.