In the architecture of a Euro VI or Tier 4 Final heavy-duty exhaust system, the diesel oxidation catalytic converter occupies a strategic position: it is typically the first major component located immediately downstream of the turbocharger. For fleet managers and automotive engineers, the DOC is defined not just by its phySICal presence but by its function as the system’s primary chemical reactor. It serves as the “gatekeeper,” conditioning the exhaust gas before it reaches the Diesel Particulate Filter (DPF) and the Selective Catalytic Reduction (SCR) unit. Unlike a passive filter that simply traps debris, the DOC actively facilitates oxidation reactions that are critical for regulatory compliance. Industry leaders like Hualian Catalyst emphasize that the efficiency of the entire aftertreatment assembly hinges on the performance of this initial stage.

Table of Contents

ToggleOxidation of Carbon Monoxide and Hydrocarbons

The fundamental purpose of a DOC catalytic converter is to neutralize carbon monoxide (CO) and unburned hydrocarbons (HC), converting them into harmless carbon dioxide (CO2) and water (H2O). Furthermore, it addresses the Soluble Organic Fraction (SOF) of particulate matter—essentially the oily residue derived from unburned fuel and lubricating oil. By oxidizing the SOF, the DOC significantly reduces the total particulate mass entering the DPF. This chemical process occurs as exhaust gases pass through the honeycomb channels coated with Platinum Group Metals (PGMs). The reaction efficiency is highly dependent on the “light-off” temperature—the point at which the catalyst becomes 50% effective. High-performance substrates provided by Hualian Catalyst are designed to reach this operational temperature rapidly, minimizing emissions during the critical cold-start phase.

Thermal Management and Active Regeneration

For experienced operators, the diesel oxidation catalytic converter is recognized as a thermal management tool. Its ability to generate an exotherm (heat) is vital for the health of the downstream DPF. When the DPF accumulates a high soot load and requires active regeneration, the engine management system injects raw fuel into the exhaust stream upstream of the DOC. The DOC catalytic converter oxidizes this fuel, creating a controlled temperature spike (often exceeding 600°C) that travels downstream to burn off the soot trapped in the filter. Without a DOC capable of sustaining these high-temperature oxidation reactions without degradation, active regeneration would be impossible, leading to filter plugging and engine derating.

Optimizing the NO/NO2 Ratio for SCR Efficiency

A less obvious but equally critical function of the diesel oxidation catalytic converter is the modulation of nitrogen oxides. While the DOC does not reduce NOx (that is the job of the SCR), it oxidizes nitric oxide (NO) into nitrogen dioxide (NO2). This is crucial because the downstream SCR catalyst operates most efficiently when the ratio of NO to NO2 is approximately 1:1, a condition known as the “Fast SCR” reaction. By converting a portion of the NO into NO2, the DOC acts as a pre-conditioner that significantly boosts the NOx conversion efficiency of the SCR system, especially at lower exhaust temperatures. This synergy underscores why the DOC substrate must be engineered for precise chemical selectivity.

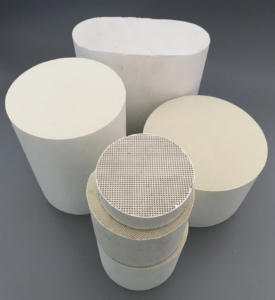

The Role of Honeycomb Ceramic Substrates

The efficacy of these chemical reactions is dictated by the phySICal structure of the catalyst. Hualian Catalyst manufactures the core honeycomb ceramic substrates that make these reactions possible. Typically made from cordierite, these substrates provide a massive geometric surface area within a compact volume. The cell density—measured in Cells Per Square Inch (CPSI)—is a critical specification. A standard DOC might utilize a 400 CPSI substrate to maximize surface contact with the washcoat. Hualian Catalyst utilizes advanced extrusion technology to ensure that the wall thickness is minimized to reduce thermal mass (allowing faster heat-up) while maintaining the mechanical strength required to withstand the vibrational stresses of heavy-duty engine operation.

Balancing Backpressure and Flow Dynamics

Inserting any component into the exhaust stream creates resistance, known as backpressure. Excessive backpressure reduces the engine’s volumetric efficiency, leading to increased fuel consumption and turbocharger lag. A well-engineered diesel oxidation catalytic converter must balance high filtration efficiency with low pressure drop. This is achieved through the laminar flow characteristics of the honeycomb design. By ensuring uniform channel sizes and smooth wall surfaces, manufacturers can minimize turbulence. Hualian Catalyst focuses on the precision of our ceramic extrusion to prevent channel deformation, ensuring that the exhaust gas flow is distributed evenly across the face of the catalyst, which prevents localized hotspots and maximizes the utilization of the precious metal coating.

Durability Against Chemical Poisoning

In the harsh environment of a diesel exhaust stream, the DOC catalytic converter is constantly bombarded with contaminants. Sulfur from fuel, as well as phosphorus and zinc from lubricating oil additives (ZDDP), can accumulate on the catalyst surface, masking the active sites and reducing efficiency. This phenomenon, known as chemical poisoning, is a primary cause of premature failure. While the washcoat chemistry plays a role in resistance, the ceramic substrate must also be robust. It must resist the formation of eutectics (lower melting point compounds) that can result from the reaction of these contaminants with the ceramic material at high temperatures. High-purity cordierite substrates are essential for preventing structural degradation in chemically aggressive environments.

Conclusion: The Foundation of Clean Diesel

The diesel oxidation catalytic converter is a sophisticated component that performs multiple simultaneous roles: oxidizer of pollutants, generator of heat, and regulator of gas composition. It is the foundation upon which the rest of the emission control system stands. For OEMs and aftermarket distributors, sourcing high-quality ceramic substrates is the first step in ensuring that this foundation is solid. Hualian Catalyst provides the industry with the robust, high-precision honeycomb ceramics necessary to meet the demanding requirements of modern diesel engines. By choosing superior substrates, operators ensure that our vehicles remain compliant, efficient, and operational in a regulatory landscape that demands nothing less than perfection.