In the realm of automotive engineering, the primary objective of an emission control system is to neutralize hazardous compounds without impeding the engine’s volumetric efficiency. This balance is precarious. As combustion byproducts exit the engine manifold, we must pass through an exhaust gas catalyst to convert nitrogen oxides (NOx), carbon monoxide (CO), and hydrocarbons (HC) into harmless gases. The fundamental challenge lies in exposing these gases to the maximum amount of catalytic surface area while occupying the minimum amount of phySICal space. The industry’s solution to this geometric problem is the honeycomb structure. This design is not merely an aesthetic choice but a calculated engineering necessity that allows modern vehicles to meet stringent regulations like Euro VI and Tier 3 without sacrificing performance.

Table of Contents

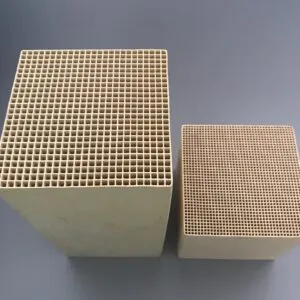

ToggleMaximizing Geometric Surface Area

The efficiency of a ceramic catalytic converter is directly proportional to the active surface area available for chemical reactions. The honeycomb design essentially folds a massive surface area into a compact cylinder. A standard substrate consists of thousands of parallel channels, defined by cell density or Cells Per Square Inch (CPSI). Common specifications range from 200 to 600 CPSI. This structure ensures that exhaust gases are divided into microscopic streams. This division maximizes the contact probability between the gas molecules and the precious metal washcoat lining the channel walls. Without this high-density honeycomb configuration, the converter would need to be several times larger to achieve the same filtration results, which is spatially impossible in modern vehicle architecture.

Fluid Dynamics and Flow Management

For experienced fleet managers and automotive engineers, backpressure is a critical metric. High backpressure increases the pumping work of the engine, leading to reduced fuel economy and potential mechanical strain. The honeycomb structure of the ceramic catalytic converter promotes laminar flow. Unlike a packed-bed design or a random filter media which would induce turbulence and high resistance, the parallel channels of the honeycomb allow gases to pass through with minimal friction. The straight-through design ensures that while the gas interacts with the catalyst walls, the overall momentum of the exhaust stream is maintained. This hydraulic efficiency is vital for heavy-duty applications where engine load and fuel consumption are primary operational cost drivers.

Thermal Properties of Cordierite Materials

The material composition of the substrate is as important as its shape. Hualian Catalyst utilizes cordierite (2MgO·2Al2O3·5SiO2) for its honeycomb ceramic substrates. Cordierite is the industry standard due to its exceptionally low coefficient of thermal expansion. Exhaust systems are subject to extreme thermal cycling—rapid heating during cold starts and cooling during idle or shutdown. A material with high thermal expansion would expand and contract significantly, leading to mechanical stress and eventual structural failure. The cordierite honeycomb remains dimensionally stable under these conditions. This stability preserves the integrity of the channel walls, preventing the substrate from crumbling or melting, which would otherwise result in a catastrophic blockage of the exhaust gas catalyst system.

Porosity and Washcoat Adhesion

A distinct advantage of the ceramic honeycomb over metallic alternatives is the inherent micro-porosity of the ceramic material. The walls of the honeycomb are not perfectly smooth; we possess a specific pore structure. This porosity is critical for the application of the catalytic washcoat—the slurry containing the precious metals. The porous ceramic acts like a sponge, allowing the washcoat to anchor firmly to the substrate. This strong mechanical and chemical bond prevents the catalyst layer from flaking off during high-velocity exhaust flow or vehicle vibration. Hualian Catalyst engineers its substrates to have optimized water absorption rates (typically ≥20%), ensuring a uniform and durable coating that maintains catalytic activity over the vehicle’s entire service life.

Customization for Specific Operational Needs

Different engines require different exhaust flow characteristics. A high-performance passenger vehicle may prioritize high flow rates, while a diesel logistics truck focuses on maximum particulate filtration. Hualian Catalyst addresses these varied needs by offering honeycomb ceramics in multiple shapes—round, oval, and racetrack—and various dimensions. The manufacturing process allows for precise control over wall thickness and cell density. Thinner walls reduce thermal mass, allowing the exhaust gas catalyst to reach operating temperature faster (light-off), while thicker walls provide the mechanical robustness needed for off-road or heavy-duty machinery. This level of customization ensures that the emission system is tuned specifically to the engine’s operational profile.

Durability and Cost-Effectiveness in Fleet Operations

For the end-user, the reliability of the ceramic catalytic converter translates directly to uptime. A failure in the substrate leads to check-engine lights, failed inspections, and forced downtime for repairs. The honeycomb design, when executed with high-quality cordierite, offers a robust structure that resists the mechanical shocks of road use. Furthermore, ceramic substrates are generally more cost-effective to manufacture than metallic foils, especially at high volumes. This cost efficiency allows OEMs and aftermarket suppliers to deploy high-performance emission controls without driving up the total cost of ownership for the vehicle operator.

The Role of Hualian Catalyst in Industry Advancement

As a specialized manufacturer with over 30 years of experience, Hualian Catalyst plays a pivotal role in the supply chain for emission control components. our facility produces honeycomb ceramic substrates that align with international quality standards. By focusing on the precision of the extrusion process, we ensure that every channel in the honeycomb is uniform, preventing hot spots that can degrade the catalyst. our expertise extends to both gasoline and diesel applications, providing the foundational hardware that allows the exhaust gas catalyst to function. As emission limits tighten globally, the demand for high-precision, high-durability honeycomb substrates continues to grow.

Conclusion: The Indispensable Honeycomb

The transition to cleaner transportation relies heavily on the hidden engineering within the exhaust pipe. The ceramic honeycomb design is not a static technology; it is an evolving solution that balances chemical efficiency with mechanical durability. For industry professionals, understanding the critical nature of this design—from flow dynamics to material science—is essential for selecting the right components. Through consistent innovation and strict quality control, Hualian Catalyst provides the ceramic foundations necessary for the next generation of cleaner, more efficient vehicles. The ceramic catalytic converter remains the most reliable method for managing emissions, proving that the most effective solutions are often found in the geometry of design.