As a manufacturer focused on diesel aftertreatment solutions, Hualian Catalyst works closely with experienced users who understand the importance of correct system configuration. When we design systems that include a sic dpf, proper DOC sizing becomes essential because it determines how efficiently soot can be oxidized during regeneration. A DOC positioned upstream generates the necessary NO₂ and heat that support stable soot conversion inside the filter. Without appropriate sizing, the reaction balance may shift, causing incomplete burn-off or irregular temperature distribution. For engines using a universal dpf filter, we evaluate exhaust characteristics, space limitations, and catalyst formulation to make sure the DOC contributes effectively to wall-flow filtration performance. In all cases, our goal is to achieve reliable regeneration that protects the filter substrate and supports long-term operating stability.

Impact of Temperature, NO₂ Generation, and Flow Distribution

The regeneration performance of a sic dpf is directly influenced by the thermal profile created by the DOC. Silicon Carbide substrates tolerate higher temperatures, yet they still require consistent and predictable heat input. If the DOC is undersized, passive regeneration may not occur because of insufficient NO₂ formation, leading to soot buildup and pressure rise. If oversized, temperature spikes may accelerate ash accumulation or stress the substrate. When working with customers who require a universal dpf filter, we examine exhaust flow uniformity, catalyst loading, and engine operating cycle to select a DOC size that matches real-world duty conditions. Proper sizing ensures that passive and active regeneration interact smoothly, reducing thermal shock and preserving the internal honeycomb channels. At the same time, the DOC influences how evenly gases enter the wall-flow structure, which directly affects soot deposition patterns over extended operating hours.

Product Considerations for Effective Regeneration

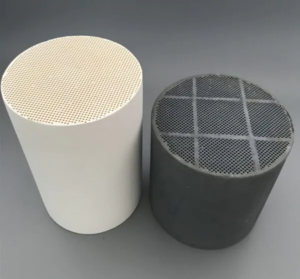

To support correct DOC–DPF matching, we provide filtration components designed for stable performance. Efficient Wall-Flow Filtration is essential for both SiC DPF and cordierite versions, as the honeycomb structure captures more than 95% of soot while maintaining smooth gas passage. High-Temperature Resistance ensures that the diesel engine particulate filter—whether silicon carbide or cordierite—remains reliable during continuous high-heat operation. Support for Passive and Active Regeneration allows soot to burn naturally when temperature permits, while active strategies supply additional energy when needed. For users integrating a sic dpf or configuring a universal dpf filter, our Customizable Specifications provide flexible options such as round or square geometry, adjustable dimensions, and cell density from 100 to 350 CPSI. These features help align DOC output with filter requirements, promoting uniform soot oxidation. In addition, Compliance with Emission Standards enables systems to meet Euro 4, Euro 5, and Euro 6 requirements without unnecessary redesign.

Conclusion

Proper DOC sizing is essential for maintaining stable regeneration performance in SiC-based filtration systems. When we develop solutions containing a sic dpf, we select DOC dimensions that balance heat generation, NO₂ formation, and flow distribution. This same approach benefits customers using a universal dpf filter, ensuring consistent regeneration and long-term durability. By combining appropriate DOC selection with our filtration products’ thermal stability, wall-flow efficiency, regeneration compatibility, and customizable specifications, we help users achieve reliable particulate control and meet their required emission targets.