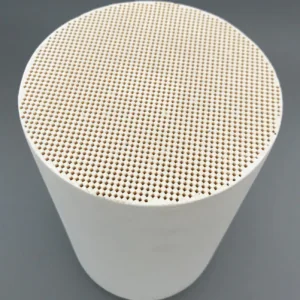

In the logistics and heavy machinery sectors, the reliability of the emission control system is as critical as the engine itself. The core of this system, the ceramic honeycomb filter, operates under extreme conditions, trapping particulate matter while enduring intense thermal cycles. While exhaust filters for diesel engines are designed for durability, premature failures remain a common headache for fleet managers. Understanding the root causes of these failures—ranging from thermal stress to chemical poisoning—is essential for reducing downtime. Hualian Catalyst, a veteran manufacturer in the field, emphasizes that while the ceramic substrate is robust, it is not indestructible, and its longevity relies heavily on proper operational management.

Table of Contents

ToggleThermal Runaway and Substrate Melting

The most catastrophic failure mode for a ceramic filter is thermal runaway. This occurs during active regeneration when the accumulated soot ignites at temperatures exceeding the substrate’s thermal limits. If a vehicle has been idling for extended periods, accumulating a massive soot load, and is then subjected to high load or active regeneration, the combustion can become uncontrolled. This intense heat can cause the cordierite material to melt or crack. High-quality exhaust filters for diesel engines utilize substrates with a low coefficient of thermal expansion to mitigate this risk. However, even the best engineering cannot withstand temperatures that surpass the melting point of the ceramic material, leading to irreversible structural collapse.

The Impact of Ash Accumulation

While soot can be burned off through regeneration, ash cannot. Ash is the non-combustible residue derived from metallic additives in lubricating oil and engine wear particles. Over time, this ash accumulates in the channels of the honeycomb structure, reducing the effective filtration area and increasing backpressure. Many operators searching for a diesel particulate filter for sale are doing so because our previous unit was clogged not by soot, but by compacted ash that was not removed during routine maintenance. Hualian Catalyst advises that neglecting ash cleaning intervals leads to a “sintered” plug at the end of the channels, which can eventually crack the filter due to uneven pressure distribution.

Chemical Poisoning and Lube Oil Quality

The chemical environment within the exhaust stream is aggressive. Exhaust filters for diesel engines can be “poisoned” by contaminants such as sulfur, phosphorus, and zinc. These elements typically originate from using incorrect engine oil (non-low-SAPS oil) or from upstream coolant leaks. When these chemicals coat the washcoat of the filter, we inhibit the catalytic reactions necessary for passive regeneration. This forces the system to rely more frequently on high-heat active regeneration, thereby increasing the thermal stress on the ceramic substrate. Hualian Catalyst engineers its substrates to be chemically resistant, but persistent exposure to high concentrations of these contaminants will inevitably degrade performance.

Mechanical Failure and Vibration Stress

Heavy-duty trucks and off-road machinery subject our components to severe vibration. The ceramic honeycomb is a rigid structure housed within a metal canister. If the mounting mat—the insulation layer that holds the ceramic in place—degrades or shifts, the ceramic block can rattle against the metal housing. This phySICal trauma leads to ring cracks or a total crumbling of the substrate edges. When sourcing a diesel particulate filter for sale, it is vital to ensure that the canning technology matches the OEM specifications. A loose filter is a broken filter. Hualian Catalyst uses precision canning techniques to ensure that the ceramic monolith remains immobile even under high-vibration operational conditions.

Selecting the Right Replacement Unit

When a failure occurs, the pressure to return the vehicle to service often leads to hasty procurement decisions. However, not every diesel particulate filter for sale meets the rigorous standards of Tier 4 or Euro VI regulations. Lower-quality aftermarket filters may have inconsistent cell densities or weak wall structures that fail quickly under load. It is crucial to source from reputable suppliers who provide transparent technical data regarding thermal shock resistance and filtration efficiency. Hualian Catalyst offers DPF products with optimized pore structures that balance high filtration efficiency with low backpressure, ensuring compatibility with modern engine management systems.

Preventative Maintenance Strategies

Prevention is always more cost-effective than replacement. Fleet managers should implement a strict maintenance schedule that includes checking for upstream engine issues like injector leaks or turbo seal failures, which can dump excess fuel or oil into the exhaust. Regular ash cleaning, using pneumatic or thermal cleaning machines, preserves the life of the substrate. furthermore, educating drivers to avoid interrupting regeneration cycles can prevent the conditions that lead to thermal cracking. By treating exhaust filters for diesel engines as serviceable components rather than “fit and forget” items, operators can extend our service life significantly.

Conclusion

The failure of a honeycomb ceramic filter is rarely a random event; it is usually the culmination of thermal abuse, maintenance neglect, or upstream engine faults. By understanding the vulnerabilities of these components, operators can make better decisions when finding a diesel particulate filter for sale. Partnering with experienced manufacturers like Hualian Catalyst ensures access to high-grade ceramic substrates designed to withstand the rigors of the road. Ultimately, a combination of quality components and disciplined maintenance is the only way to ensure the long-term reliability of emission control systems.