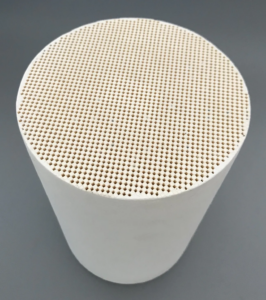

When it comes to selecting the right diesel particulate filter (DPF), two main materials dominate the industry: Cordierite DPF and SiC DPF. Both of these options are specifically engineered to effectively reduce particulate emissions from diesel engines, helping vehicles comply with increasingly stringent emission regulations such as Euro 4, Euro 5, and Euro 6. Choosing the appropriate filter, however, depends on multiple factors including the vehicle’s operating environment, typical driving conditions, fuel quality, and specific engine requirements. Factors such as temperature tolerance, regeneration efficiency, and overall durability also play a critical role in determining which material is most suitable for a given application. In this article, we will provide a detailed comparison of these two materials in terms of performance, lifespan, thermal stability, and their suitability for different types of vehicles and operating conditions.

Durability and High-Temperature Resistance

One of the primary differences between SiC DPF and Cordierite DPF lies in their resistance to high temperatures. The SiC DPF is made from silicon carbide, a material known for its excellent high-temperature stability. This makes SiC DPF the ideal choice for vehicles that frequently operate under extreme conditions, such as those in the mining or construction sectors.

On the other hand, Cordierite DPF, while still resistant to high temperatures, is better suited for light to medium-duty vehicles that experience less intense exhaust temperatures. Cordierite is durable enough to handle most everyday driving scenarios but may not withstand prolonged high temperatures as effectively as SiC DPF.

Regeneration Process: Passive and Active Support

Both SiC DPF and Cordierite DPF support passive and active regeneration. Passive regeneration occurs when the exhaust temperature is sufficiently high, allowing the soot collected in the filter to burn off naturally during regular driving. If the temperature is not high enough, active regeneration is triggered, where additional heat is applied to burn off the soot.

While both types of filters support these regeneration processes, SiC DPF often performs better in maintaining consistent regeneration under varying conditions, particularly in vehicles that require frequent active regeneration cycles.

Conclusion

In conclusion, both SiC DPF and Cordierite DPF offer excellent performance in reducing diesel particulate emissions, but the choice between the two largely depends on the specific needs of your engine and operational environment. SiC DPF excels in high-temperature and heavy-duty applications, while Cordierite DPF is more suited for light to medium-duty vehicles. At Hualian Catalyst, we provide high-quality, customizable DPF solutions that ensure compliance with emission standards and enhance the performance of your vehicle. Choose the right filter for your engine to improve fuel efficiency and reduce environmental impact.