As Hualian Catalyst, we work with customers who require dependable emission-control solutions for demanding diesel applications. When discussing the main purpose of a diesel oxidation catalytic converter, we focus on how this component supports efficient after-treatment performance in modern diesel engines. In our work, we apply the doc catalyst to help convert harmful exhaust compounds into more stable and environmentally acceptable substances. Through reliable chemical oxidation supported by stable thermal characteristics, the system plays an important role in meeting regulatory expectations while maintaining equipment performance.

How the DOC Catalyst Functions in Diesel After-Treatment Systems

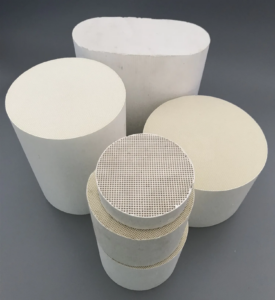

In our emission-control product line, the DOC Catalyst–Honeycomb Ceramic Structure is used to provide consistent oxidation efficiency. Built on a durable honeycomb ceramic substrate, our system enables exhaust gas to pass through evenly, allowing the oxidation reaction to take place across a large surface area. This design helps the diesel oxidation catalytic converter convert carbon monoxide, hydrocarbons, and soluble organic fractions into carbon dioxide and water. Our doc catalyst maintains low pressure drop, stable thermal behavior, and continuous catalytic activity, which support the needs of heavy-duty diesel engines, non-road machinery, and construction equipment. By positioning the catalyst at the front of the after-treatment sequence, we ensure that downstream components, including particulate filters and selective reduction systems, receive cleaner exhaust, contributing to stable long-term operation.

Application Benefits and Customization for Regulatory Requirements

We design each diesel oxidation catalytic converter for customers who must comply with Euro III–VI and EPA requirements. The purpose of this system extends beyond basic oxidation: it establishes proper exhaust conditions for subsequent treatment steps and helps maintain engine response and operational stability. Our DOC catalyst supports consistent conversion efficiency during variable load cycles, which is essential for equipment that operates continuously or under fluctuating conditions. The DOC Catalyst–Honeycomb Ceramic Structure can be customized by cell density, substrate size, and coating formulation. In addition, our doc catalyst solutions allow customers to select features suitable for temperature resistance, emission targets, and integration with wider exhaust assemblies. Through this approach, we support compliance objectives without compromising mechanical durability or fuel performance.

Conclusion: The Core Role of a DOC Catalyst in Emission Control

In summary, the main purpose of the diesel oxidation catalytic converter is to oxidize harmful exhaust compounds and create stable upstream conditions for the full after-treatment system. Within our product line, the doc catalyst fulfills this role through its honeycomb ceramic design, steady thermal characteristics, and adaptable coating configurations. As Hualian Catalyst, we focus on delivering configurations that match regulatory expectations and operational demands, allowing customers to maintain dependable performance while achieving required emission-control outcomes.