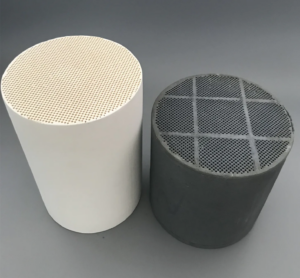

In modern diesel engine systems, diesel particulate filters (DPF) are essential components designed to capture soot and fine particles from exhaust gases, ensuring vehicles comply with strict emission regulations. At Hualian Catalyst, we offer two types of DPF solutions: the Sic DPF and the universal DPF filter, both designed to meet the unique demands of different diesel engine applications. The material choice in a DPF is crucial for its performance and durability, particularly under the extreme temperatures typical in diesel engine exhaust systems. Among the various materials used in DPF construction, Silicon Carbide (SiC) is the material of choice for high-temperature applications due to its superior performance and longevity.

Benefits of Silicon Carbide (SiC) in DPF Applications

One of the primary reasons Silicon Carbide is favored for DPF applications is its excellent thermal conductivity and high mechanical strength. In heavy-duty diesel engines, which operate under high thermal stress, a DPF needs to withstand extreme heat while maintaining its structural integrity. Silicon Carbide DPFs excel in this regard, as they can endure the high temperatures generated in such environments. In comparison to other materials like Cordierite, SiC offers better resistance to thermal shock, ensuring the filter performs reliably even under the most challenging conditions. This enhanced durability leads to a longer service life, which is especially beneficial for heavy-duty vehicles that require extended periods of operation without maintenance.

At Hualian Catalyst, our SiC/Cordierite DPF systems feature a sophisticated wall-flow honeycomb structure that effectively traps over 95% of particulate matter, meeting stringent Euro IV-VI emission standards. This highly efficient filtration ensures that the engine operates smoothly and efficiently while maintaining the required emissions standards. SiC DPFs are well-suited for heavy-duty engines, where performance and durability are essential.

Cordierite vs. Silicon Carbide DPFs

While Cordierite DPFs are a popular choice for light-duty vehicles, Silicon Carbide DPFs are designed for more demanding applications. Cordierite DPFs are lightweight, cost-effective, and offer good thermal shock resistance, making them ideal for urban driving and light-duty applications where the filter may undergo rapid temperature changes. On the other hand, Silicon Carbide is particularly suited for heavy-duty vehicles, such as trucks, buses, and construction vehicles, where higher temperatures and extended operation periods are common. The SiC DPF offers enhanced strength and durability under these conditions, ensuring optimal performance over a longer lifespan, even under harsh driving environments.

Conclusion

In conclusion, when it comes to selecting the ideal material for diesel particulate filters, Silicon Carbide stands out due to its superior thermal resistance, mechanical strength, and longevity, making it the preferred choice for high-temperature diesel engine applications. At Hualian Catalyst, we offer high-performance SiC/Cordierite DPF solutions that deliver reliable, long-lasting filtration, ensuring compliance with emission standards while maintaining engine efficiency. Whether for light-duty or heavy-duty applications, our DPF products are designed to meet the diverse needs of the modern diesel engine market.